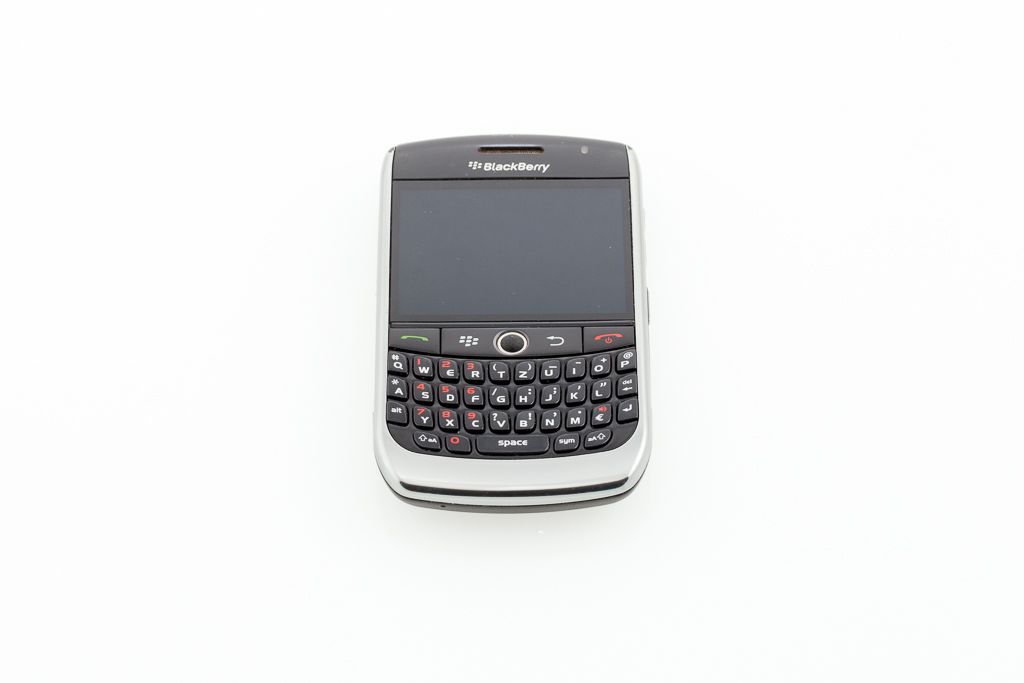

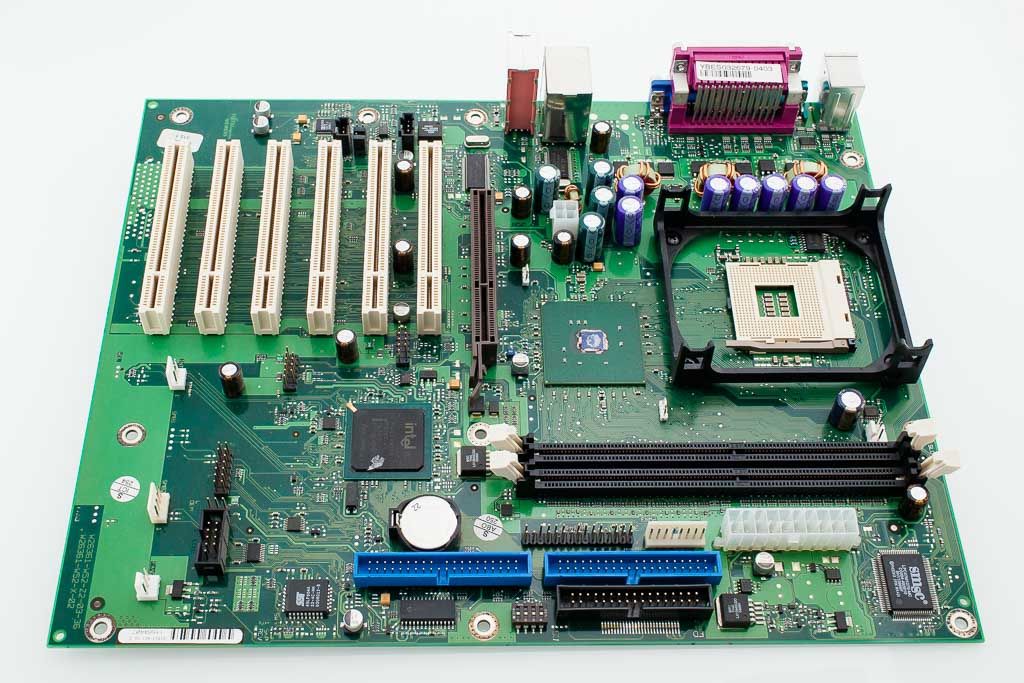

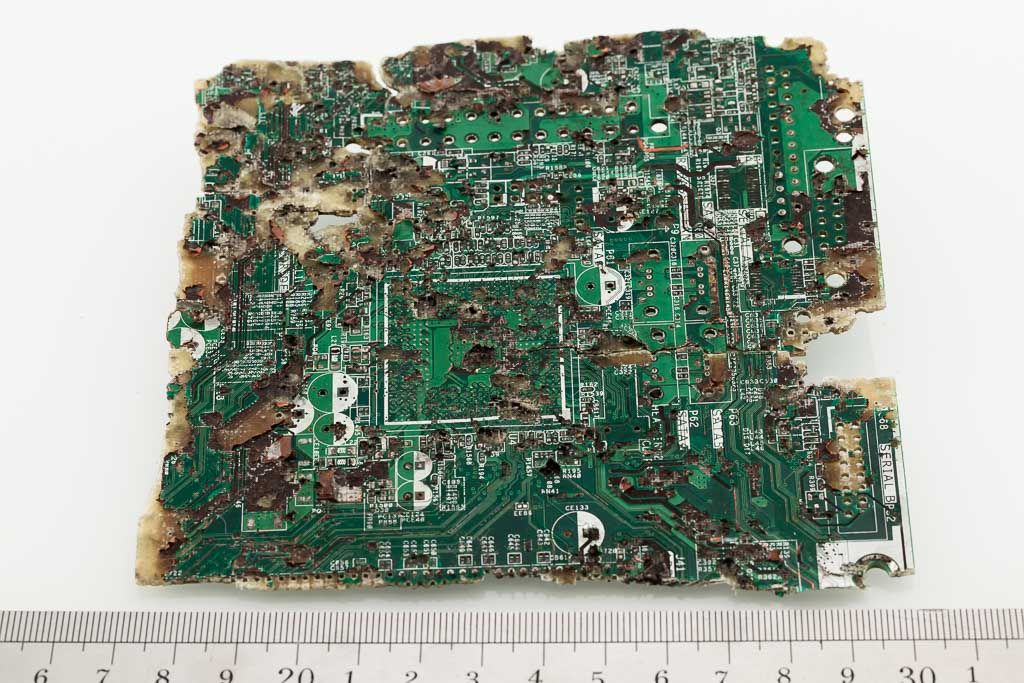

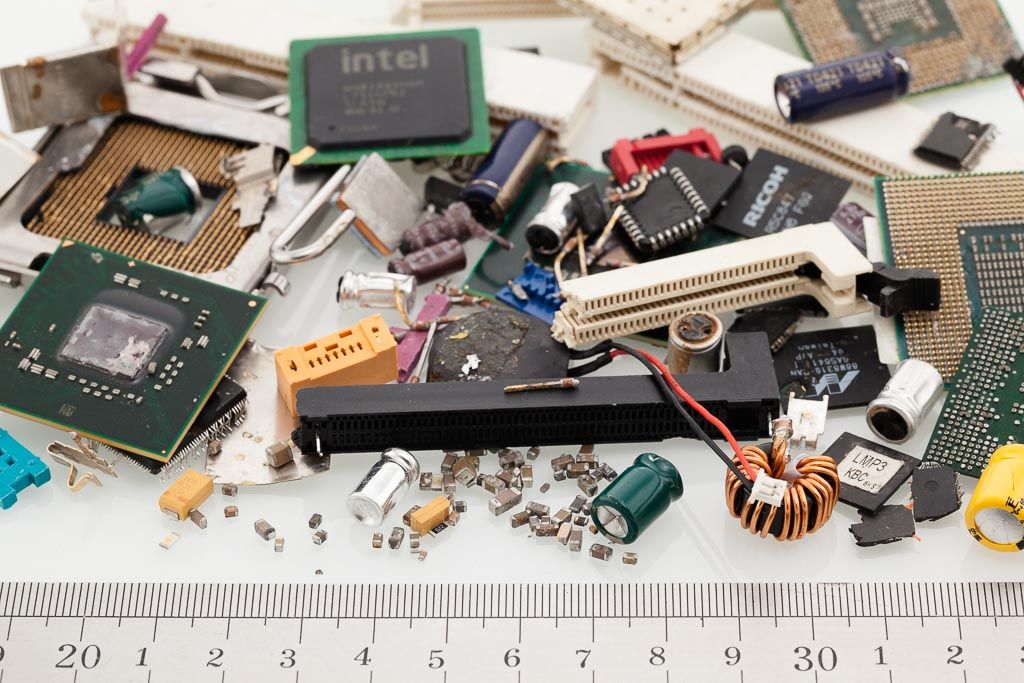

ImpulsTec’s fragmentation systems can be used for disassembly of complex devices such as mobile phones and laptops into components, for detaching of electronic components from printed circuit boards and the separation of components such as processors and tantalum capacitors into their different materials.

The homogeneous energy input of the shock wave process into the device leads to the break up of the assemblies at their mechanical weak points, which are typically joints and interfaces between different materials. This allows electronic equipment to be almost perfectly separated into their main components, such as frame parts, printed circuit boards, and other plastic or metal pieces.