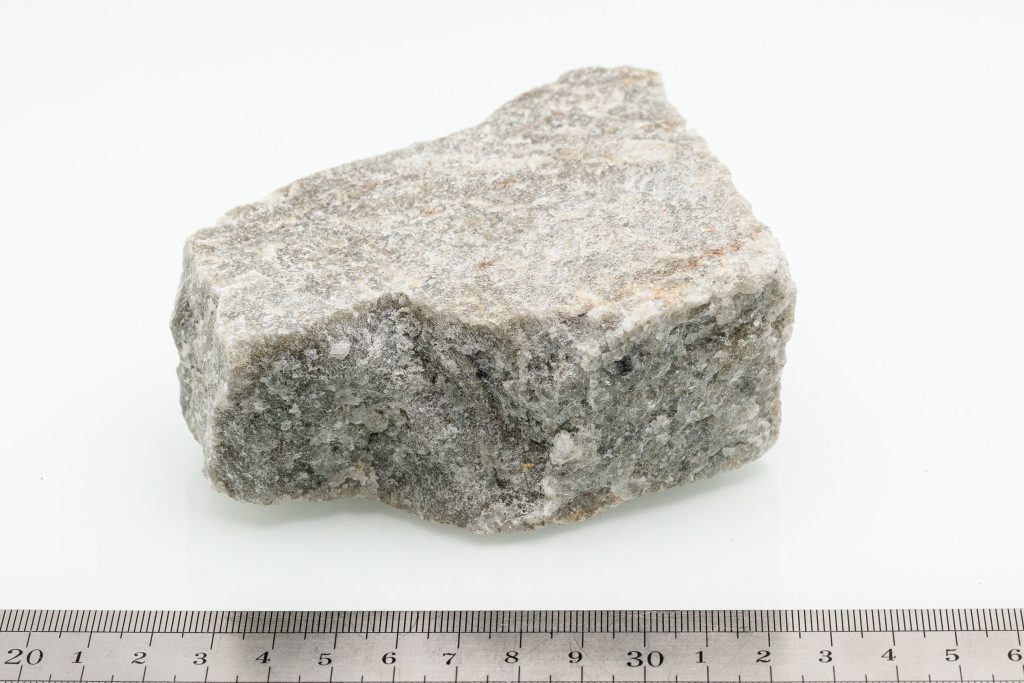

Due to its specific separation mechanism, the shock wave process, which provokes fractures on the crystallographic level at the interfaces of different materials, is particularly suitable for processing intermediate mining products and for crushing rock, minerals or slags with valuable ingredients.

The specific separation mechanism of shock wave technology has a particularly positive effect on rock processing, which provokes material fractures, preferably at the interfaces of materials with different acoustic properties. The selectivity of the fragmentation process on crystallographic (foreign) phases enables the efficient disintegration of different microstructures.

The process offers great potential for processing valuable mining products and minerals. Shock wave fragmentation technology is able to recover and concentrate the valuable materials contained in rocks. This technology could potentially improve the efficiency of conventional processing methods in future. Over the last few years the shock wave fragmentation process extended to industrial scale. We are continually expanding the scale of the technology and developing customer-specific solutions in collaboration with an expert network of national and international partners from every field.