The shock wave fragmentation process marketed by ImpulsTec can also be used to treat devices containing hazardous industrial materials into their individual components, so that the valuable substances can be separated from the hazardous parts and recovered. This suggests a variety of possible applications of shock wave technology to improve the efficiency of existing processes or develop entirely new recycling approaches.

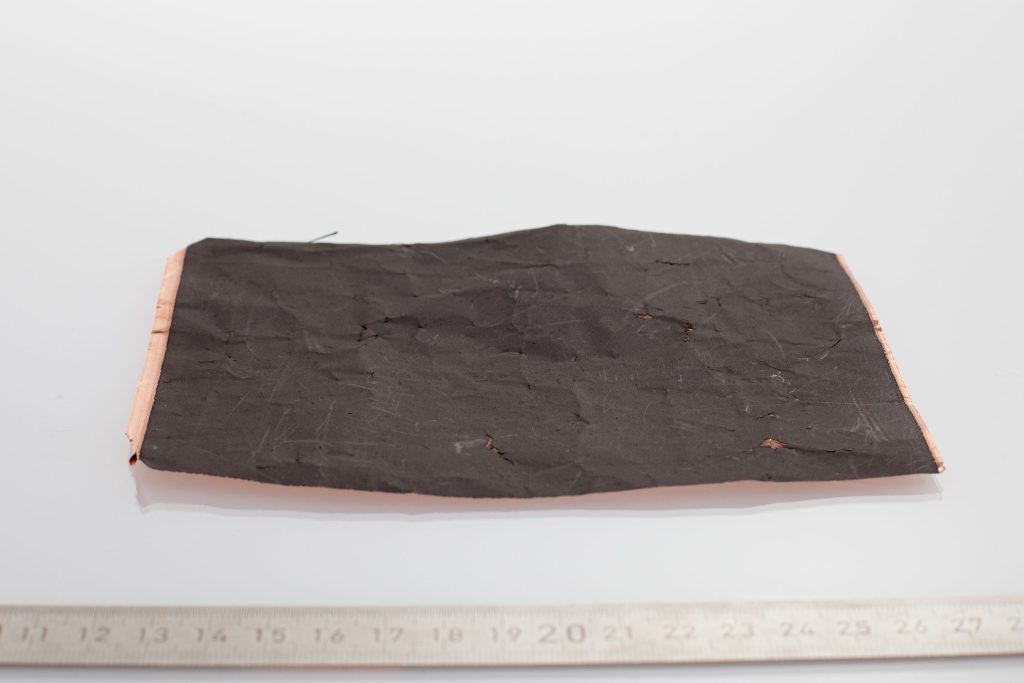

Since the process is conducted within a fluid fragmentation medium, Li-ion battery cells for example can be safely dismantled, which also offers the possibility of functional recycling of the recovered active material as well as material based recycling of the components. Furthermore, the shock wave process can also be used for the gentle disassembly of assemblies containing hazardous substances, in order to subsequently enable a separating processing of hazardous and non-hazardous components.