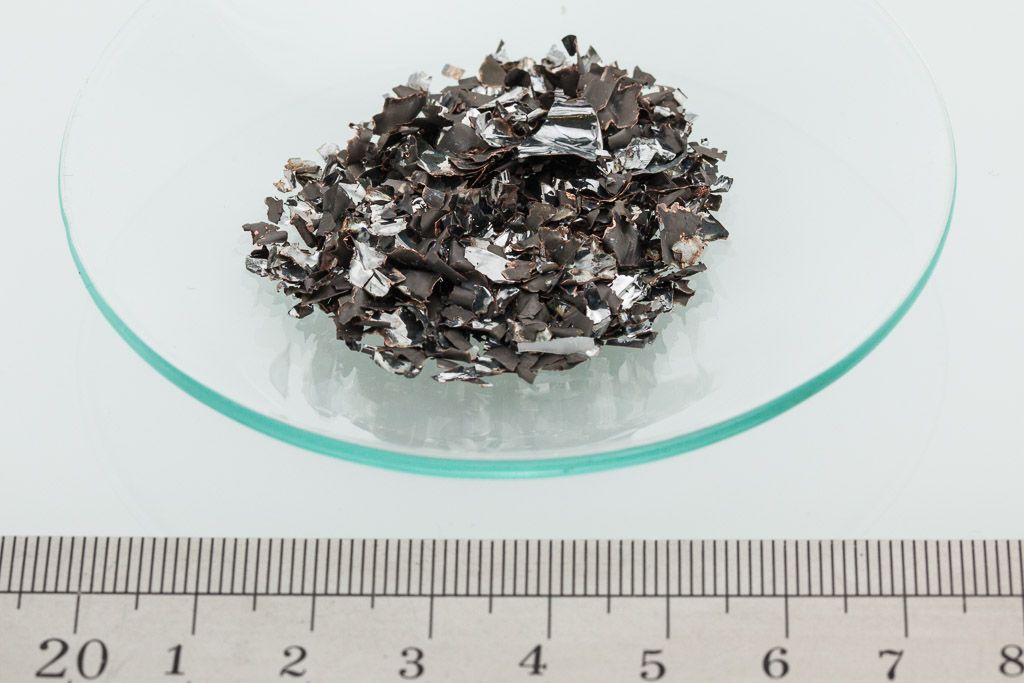

A promising area of application for the shock wave process is the recycling of composite materials and composites such as photovoltaic modules or carbon fiber reinforced plastics. In addition to the separation of the materials into their pure individual components, ImpulsTec’s selective fragmentation technology offers even more efficient possibilities of recycling, namely the “functional recycling”. The latter indicates a shift from a pure element / material driven recycling towards a removal of intact composites and complete substructures that are reused in the original application or production process.

The selectivity achievable with the shock wave fragmentation process depends on the mechanical and acoustic properties of the composite materials. The fact that each material can be non-destructively recovered allows new recycling approaches to be imagined, away from a pure material recycling towards a functional recycling.

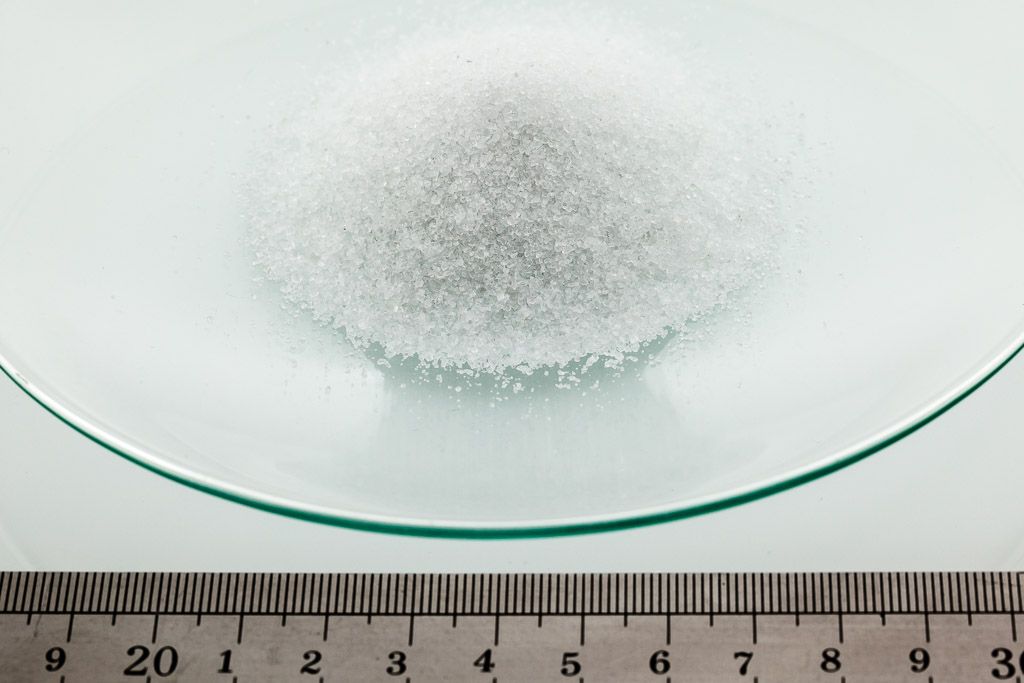

One possible application of the shock wave process is the recycling of solar modules, allowing both the semiconductor material and the high-quality front glass to be recovered while meeting the high purity requirements associated with these materials.

The shock wave fragmentation from ImpulsTec is ideally suited for detaching thin coatings from substrates. Depending on the mechanical integrity of their materials, some substrates will remain largely structurally intact, while others will also be fragmented. The minimum thickness of the detachable layer depends on the combination of materials and the physical properties of the objects to which they are bound. In several research and customer projects it was possible to detach layer thicknesses down to less than 10 µm using the shock wave method.